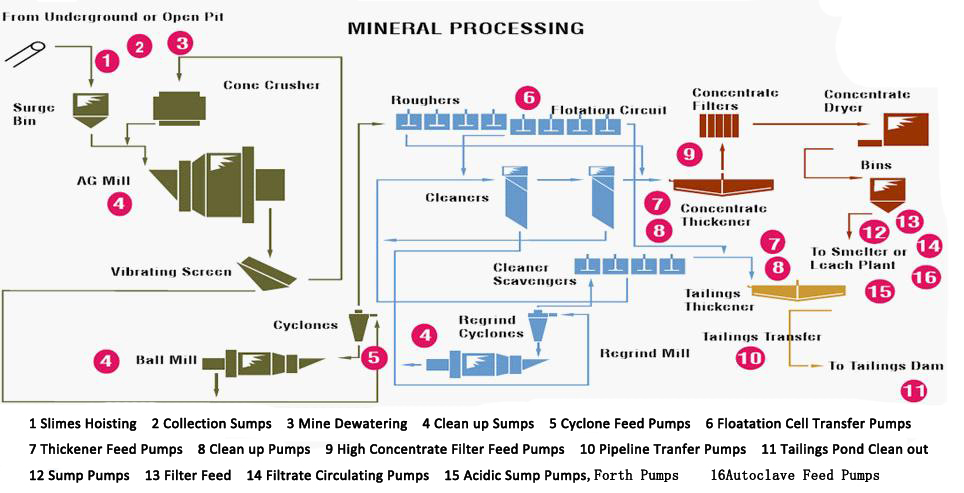

Mineral Processing

mineral processing is a course that by physical or chemical methods, separate useful mineral raw materials and useless (usually called gangue mineral) or harmful minerals, or separate various useful mineral raw materials.

The process is according to the physical and chemical properties of different minerals in ores, after ore spalling and crushing grinding, adopt gravity separation, flotation method adopted, magnetic separation, and electrostatic separation method, separate useful mineral raw materials and gangue mineral, and separate various symbiotic useful mineral raw materials as far as possible form each other. Then remove or reduce harmful impurities, in order to obtain needed raw materials of smelting or other industrial.

Development: As an important part of ore dressing production process, mineral processing has been always aroused more attention. While mining enterprises is rebuilding the system, besides put development correct direction, also needs the enterprises to focus on equipment reformation and mineral processing technology innovation.

1 Slimes Hoisting

2 Collection Sumps

3 Mine Dewatering

4 Clean up Sumps

5 Cyclone Feed Pumps

6 Floatation Cell Transfer Pumps

7 Thickener Feed Pumps

8 Clean up Pumps

9 High Concentrate Filter Feed Pumps

10 Pipeline Transfer Pumps

11 Tailings Pond Clean out

12 Sump Pumps

13 Filter Feed

14 Filtrate Circulating Pumps

15 Acidic Sump Pumps, Forth Pumps

16 Autoclave Feed Pumps