The pump can be used in many applications, such as Pipeline transport, High velocity hydraulic transport, Mineral processing, Coal prep, Cyclone feeds, Aggregate processing, Fine primary mill grinding, Chemical slurry service, Tailings, secondary grinding, Industrial processing, Pulp and paper, Food processing, Cracking operations, Ash handling.

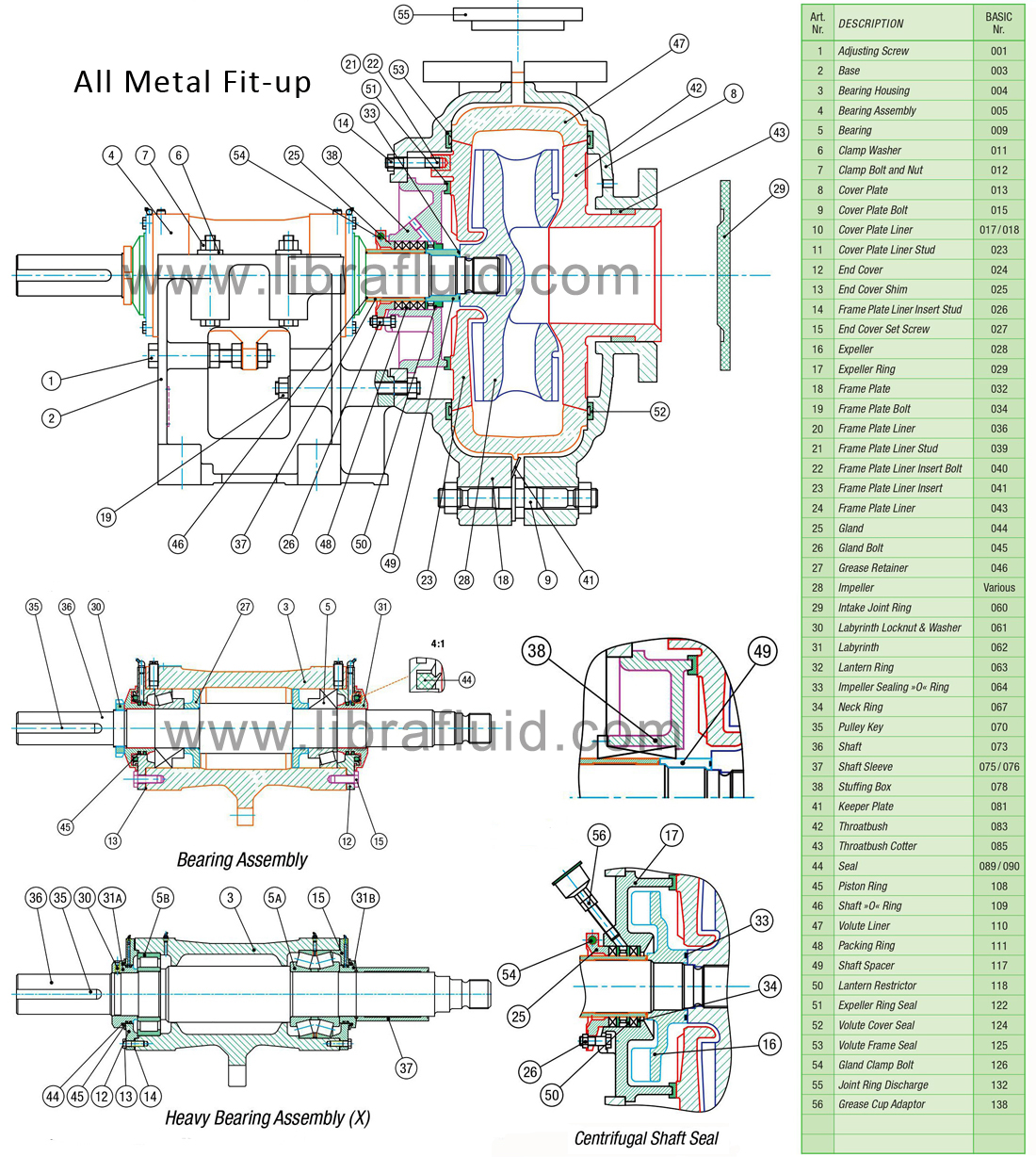

High chrome slurry pump assembly drawing

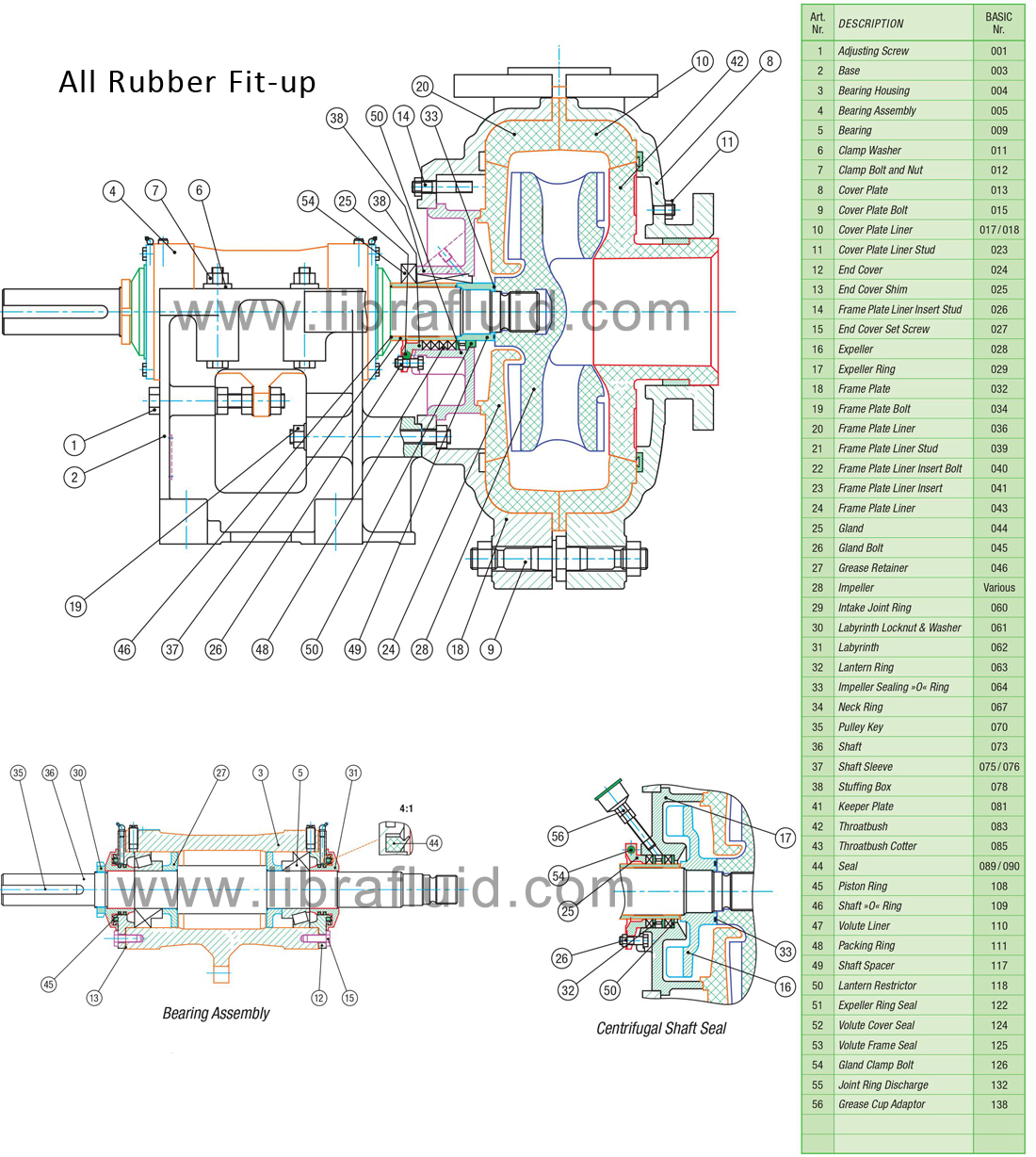

Rubber slurry pump assembly drawing

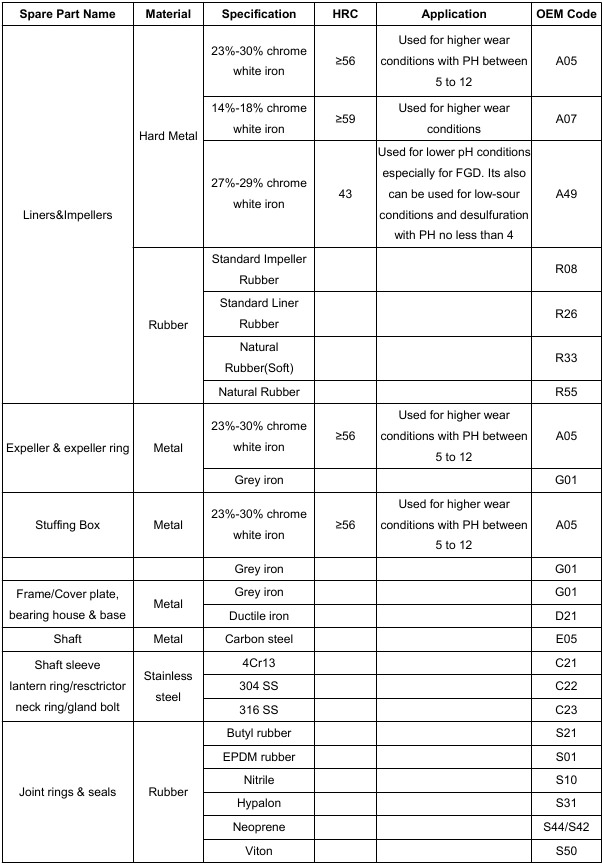

Slurry pump spare parts material list

| H series slurry pump model list | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| The above performance is based on clean water test |

H series Slurry Pump Structure

Slurry Pump Wetted Parts

Liners – Hard metal liners are completely interchangeable with pressure molded elastomer. Elastomer seal rings back all liner joints. Easily replaceable liners are bolted, not glued, to the casing for positive attachment and east of maintenance.

Impeller – Hard metal and molded elastomer impellers are completely interchangeable. Front and rear shrouds have pump out vanes that reduce recirculation and seal contamination.

Throat bush – Hard metal and molded elastomer impellers are completely interchangeable. Wear is reduced and maintenance simplified by the use of tapered mating faces to allow positive accurate alignment during assembly and simple removal.

Parts No.

018:Cover Plate Liner

013:Cover Plate

032:Frame Plate

036: Frame Plate Liner

041: Frame Plate Liner Insert

060: Intake Joint

083:Throat bush

110:Volute Liner

122: Stuffing Box Seal

124: Volute Cover Seal

132: Discharge Joint

147: Impeller

H series Slurry Pump Shaft Seal

Gland Seal

Most popular type of seal. Clean water at a certain pressure being injected into the packing through the lantern restrictor, preventing leakage from casing.

Expeller Seal

The expeller generate a reverse centrifugal force to prevent the leakage. Suitable for most slurry pumping applications providing a major advantage where no gland water is required.

Mechanical Seal

Mechanical seal is used for applications where no extra substance is allowed to mix with the fluid being pumped, such as chemical or food industry.