Slurry Pump Manufacturer

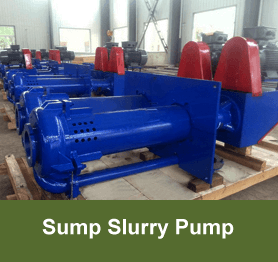

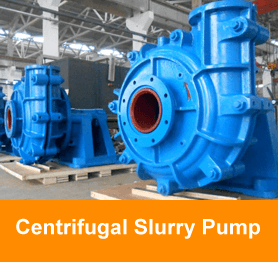

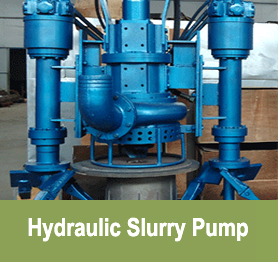

Libra launched its slurry pump factory since 1999. We are professional in wear and abrasive resistance material. We aim to lower pump operating and maintenance costs when dealing the with toughest and high-wear applications.

We are one of the industry’s best source for supporting heavy duty centrifugal slurry pumps in industries like hard rock mining, mineral processing, power generation, aggregate production, or any type of slurry pumping application.

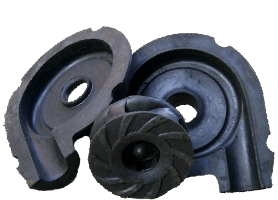

Reliable Replacement Slurry Pump Parts Factory!

Libra manufactures quality slurry pump replacement parts 100% compatible with famous slurry pump. As one of the best slurry pump manufacturer, we provide value to customers through fair pricing and short lead time in the market. Now we can supply replacement slurry pump parts in High chrome, Elastomer, Ceramic and Polyurethane, special material can be done as required.

High chrome pump parts are made of 26-28% high chrome metallurgy has a guaranteed HRC58+ hardness. Variety of metallurgies are available for more corrosive applications.

Our elastomeric parts are designed to provide longer life and abrasion resistance in a variety of applications. Now natural rubber and synthetic elastomers are majority material of slurry wetted parts.

Ceramic pump parts are made of Silicon Nitride Bonded Silicon Carbide, aimed to Wear and Erosion resistant working application, such as coal power generation, non-ferrous foundry, mining and etc.

Polyurethane is an erosion resistant material that performs well in elastomer applications where ‘tramp’ is a problem. This is attributed to the high tear and tensile strength of Polyurethane.