When you instal the slurry pump, you must have the pipe system done there to let the pump work. And there are some factors you should pay attention to, such as

1. The inlet side pip segment upturned

This will cause water gathered air inside pipeline, decrease the degree of vacuum pipe system and slurry pumps, make the pump suction distance less and reduce water pumped out.

2. Too many elbows in suction line

Too many elbows in pipe line will lead to heavier flow resistance. And all these elbows should be in 90 degree, do not allow extent turning direction, which may gather air in the pipeline

3. Small pipe diameter size

Many people think that this can increase the pump head, working head = total head – loss of head. Total head is inevitable for one pump. The pipeline friction force reduce the head in fact, so smaller pipe diameter will increase more loss for the slurry pump total head. Somehow, it will loss head rather than get more, and resulting in pump efficiency landing.

So, just make the pipe size suitable for the pump and if need higher head, better to change a pump at first.

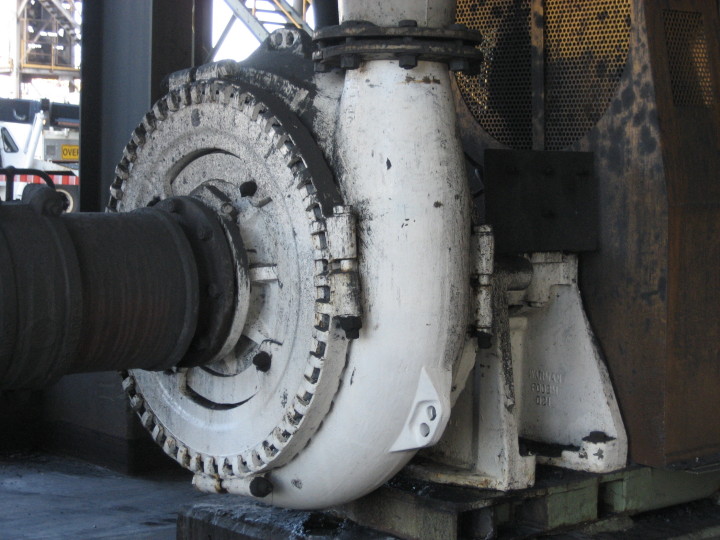

4. Pump inlet directly connect with elbow

This will make the water spread unevenly, through elbow enter the impeller. When the pipe diameter larger than the slurry pump inlet, an eccentric reducer should be installed. Eccentric reducer should be installed above the flat portion, the ramp portion mounted below. Otherwise it will gather air, lead to reducing amount of water or no water pumping, and even crash. If the inlet pipe and pump inlet diameter equal, you should install a tube between them, straight pipe length must not be less than 2 to 3 times of pipe diameter.

5. With a bottom valve in inlet pipeline and the last tube is not perpendicular

If installation like above, the bottom valve can not self-closing, will cause leakage.

Accurate method of installation: fitted bottom valve, the last tube in pipeline is perpendicular. As a result of topographical conditions can not be mounted vertically, it should axis angle with the water level surface should be 60 ° or more.

6. Not good inlet position

When the inlet pipe under water not deep enough, it will cause the water inlet swirl around, impact of suction, reduce the water into pump.

Accurate method of installation: small and medium sized pump water depth no less than 300 ~ 600mm, large pumps must not be less than 600 ~ 1000mm

7. The outlet pipe is above the normal water level in the pool

If the outlet above the normal water level in the pool, although the increase of the pump head, but reducing the flow. As a result of the limited terrain conditions, the outlet was up out of the pool water level is necessary, it should be installed in the nozzle elbow and a short tube, water pipes become siphon down the outlet height